Why it matters

Why it matters

Chrome Spiralinto Recovery

As the global leader in chrome production, South Africa faces the pressing challenge of unstable reliability in its fines processing operations. The industry demands robust equipment capable of enduring the abrasive nature of chrome extraction. Our advanced spirals excel in durability, efficiency, and reliability, outperforming competitors while maximising production in a smaller space. Embrace the future of chrome mining with our promise of enhanced longevity and profitability.

The Challenge

The Challenge

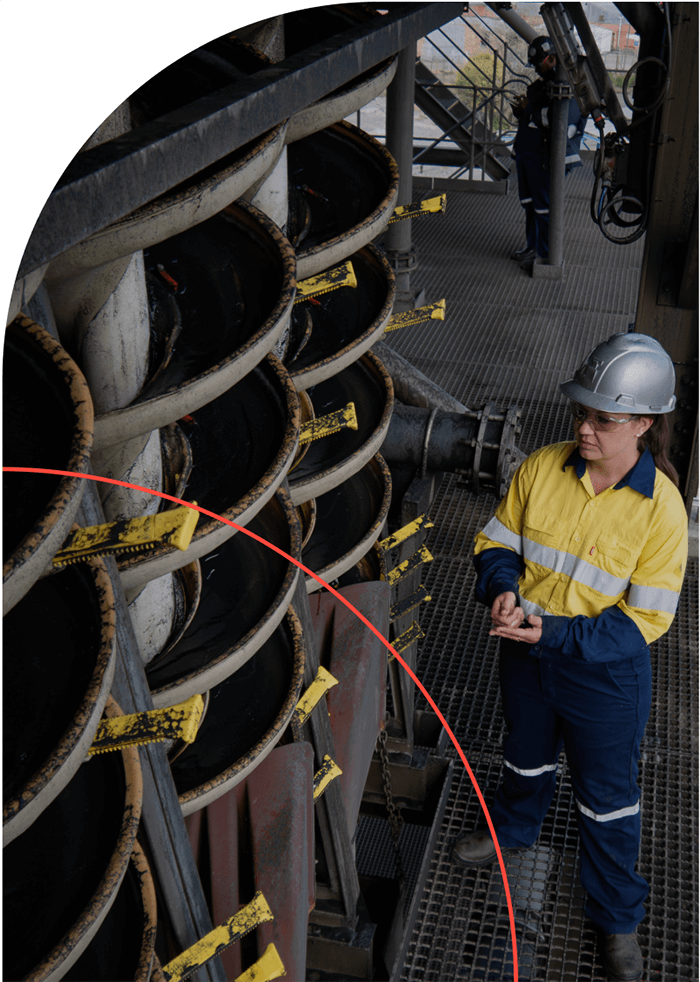

Tough onRough

Chrome mining struggles with spiral operations in beneficiation due to the high density of chromite ore, causing inefficiencies and yield losses. Fine particles and ore quality variations worsen clogging and effectiveness. Continuous optimization and innovative technologies are essential to improve efficiency and recovery rates.

Made in South Africa

So building a spiral that will outlast traditional solutions requires experience and know-how. Based on two decades of fine tuning high quality materials by trial and testing, we now offer spirals that last, with better metallurgical performance and durability, made in South Africa to our established Australian quality standards.

Our Solution

Our Solution

MT ChromeSpirals

Reliable Performance

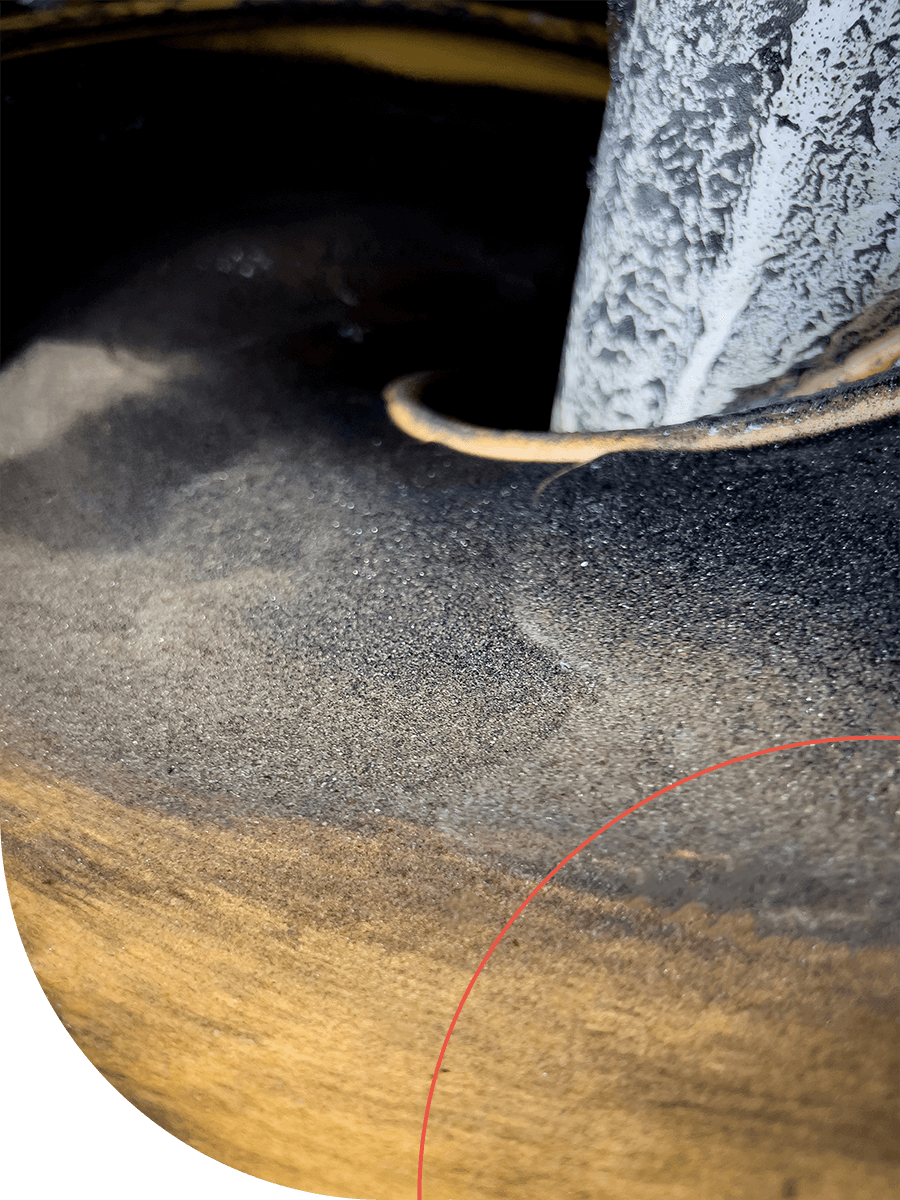

Our advanced spirals are engineered to provide consistent and reliable performance in chrome mining operations. They are made from high quality materials that have been fine tuned over years of trial and testing. Our PU is a proprietary polyurethane technology hat has been proven to last.

With over 40 spiral variations, speak to us about which spiral works for you, and kicking things off with testwork in our own mineral lab.

Both our Australian and South African facilities are ISO 9001 certified.

The thing with chrome is: You want to extract something that wears down your equipment in the long run. So make it as strong as possible.

Bucky Dunnpart

MT Chrome Specialist

The Advantages

The Advantages

Built forChrome

By improving recovery rates and ore grades, these spirals lower overall costs and boost profits, delivering a compelling return on investment with a smaller operational footprint.

Advanced spirals feature round outlet boxes that prevent common blockages, using HDPE piping to enhance durability and reduce maintenance, streamlining chrome extraction processes.

MD spirals are cost-effective, offering top performance and competitive pricing. Their robust, modular design minimises maintenance, reduces setup costs, and ensures flexibility. High recovery rates and low operational costs provide a high ROI, ideal for chrome recovery projects.

Every mining site is unique. Mineral Technologies offers customisable MT spirals tailored to specific ore characteristics and operational needs. Expert consultants ensure effective and robust solutions for efficient mining operations.

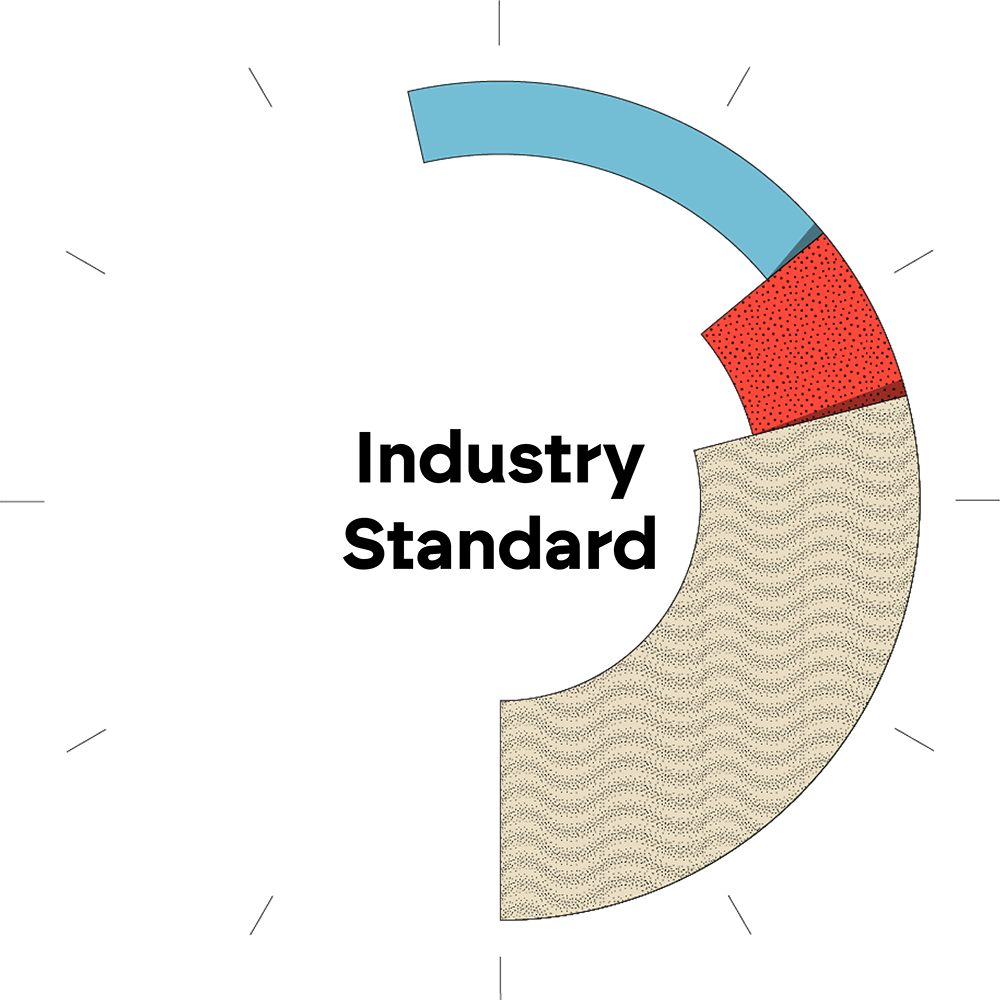

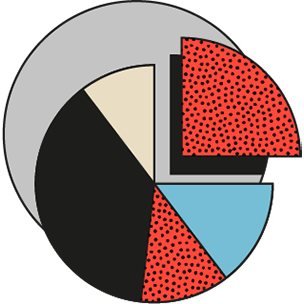

OutperformingIndustry Standards

MT spirals offer superior chrome recovery with a compact design that consumes less space in mines. This advanced technology enhances efficiency and sustainability in mineral processing.

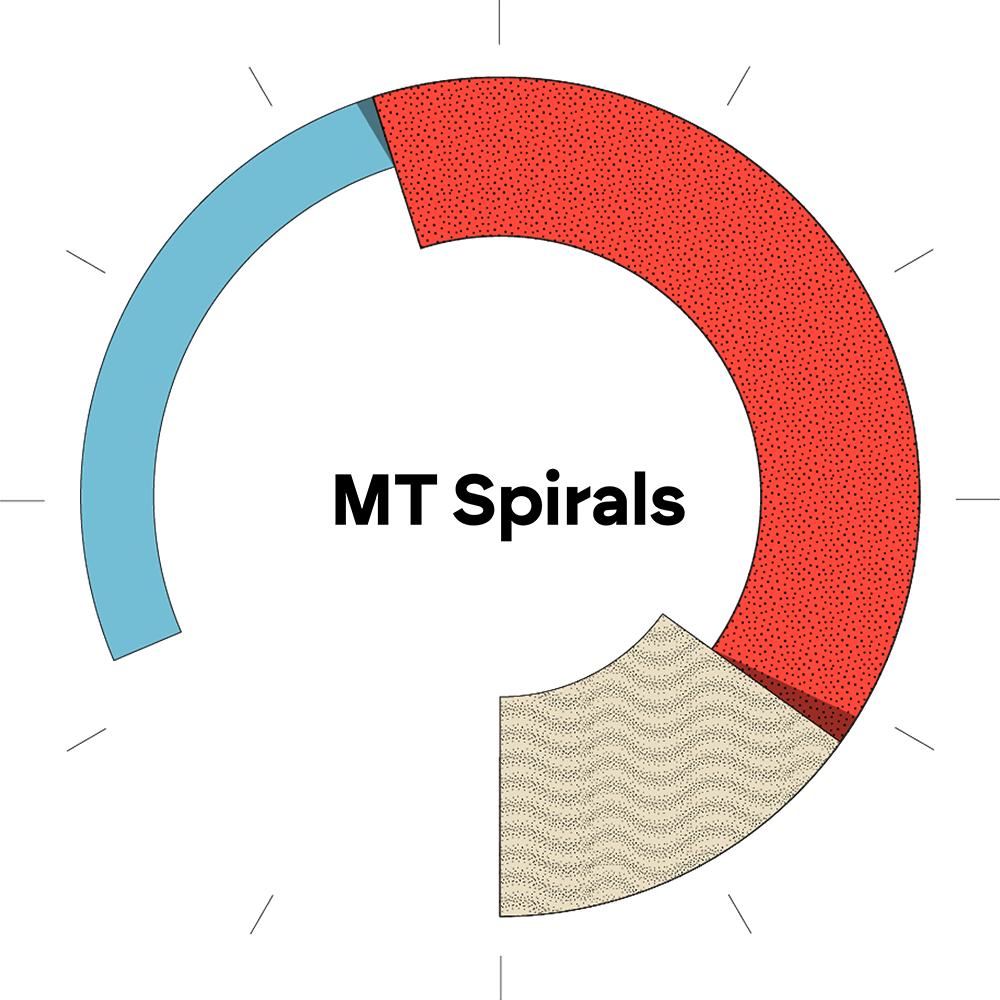

85%

Recovery Rate

15%

Average reduction in waste

<10%

Cr in tails

+1 Million

MT Spirals manufactured

Test Work

Test Work

EnhancedDecision Making

1. Accurate Analysis:

Mineral Technologies is a well-established company with expertise in inhouse Mets services (laboratory and ore analysis). Our testing services will provide you with accurate and reliable information about the composition and properties of your minerals and how you get them best.

2. Customised Solutions:

Every orebody is different. By analyzing your ore samples, we can apply the most effective spirals and other proven MT separation technologies. Benefit from MT experts support you with guidance on how to optimise the performance of your plant.

3. Improved Efficiency:

Prevent downtime, reduce maintenance needs, and minimise repairs. In operation reduce waste, increase yields, and lower operating costs. Testing your ore samples with Mineral Technologies can help you avoid costly mistakes by identifying potential issues with your current spiral separator setup.

The Experts

The Experts

ReachOut!

Ready to explore how our advanced spiral solutions can revolutionise your chrome mining operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Stephan Van Staden

Business Unit Manager Africa

Focus: Chrome

I love hands on problem solving with 22 years experience in chrome processing and optimisation.

Samson Sebaeng

Business Development Africa

Focus: Fine Minerals

Let’s drive the sustainable development of mining in Africa and create an enabling environment for responsible mining practices.

James Agenbag

Fines Beneficiacion Expert

Focus: Fine Minerals

I am a chemical engineer with two passions: physical separation and customers. Let’s solve your processing problems.

Andre Kiesling

Senior Product Engineer

Focus: Chrome

Chrome is my passion with 18 years’ experience in designing spirals for various applications as well as plant designs.

What is Next

What is Next

Spiral intoa sustainablefuture

Our spiral solutions are more than just technological innovations—they are the keys to unlocking the full potential of chrome extraction. By maximising recovery rates, reducing operational costs, and ensuring durability in harsh mining environments, our spirals not only enhance profitability but also pave the way for sustainable mining practices. As the global demand for chrome continues to rise, it is imperative that we embrace solutions that not only meet current needs but also safeguard the future of the industry. We are not just mining chrome; we are shaping the future of chrome extraction for generations to come.

Your mine, your success.Let’s chat.

To find out more about how we can work together to drive down operational cost and extra maximum value from your mineral processing operations across the project, contact our local team today.

Jolene Saaiman (MBA, B.Eng Honours, B.Eng Metallurgy)

Business Relationship Manager